Download document () of 20

Download

You have exceeded the download limit

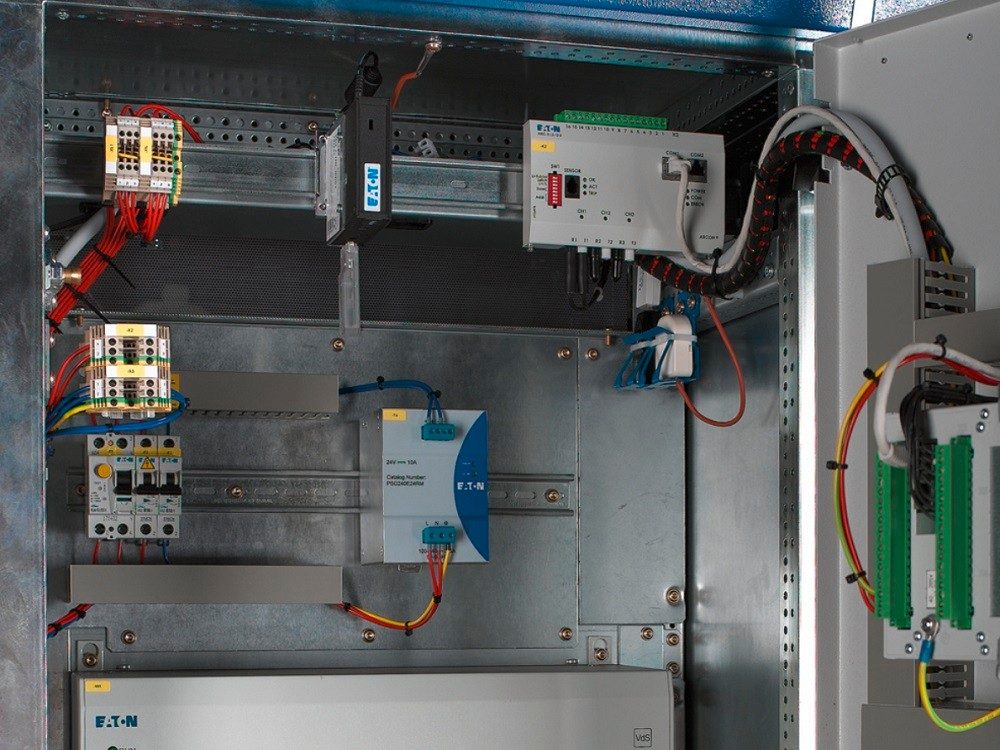

Eaton DIAGNOSE is a wireless and maintenance-free temperature monitoring system for busbar systems in LV switchgear assemblies. By continuously recording machine data, DIAGNOSE makes it possible to determine and schedule the right time for maintenance. This helps you to reduce downtime, increase system availability and avoid recurring costs for thermal screening.

Temperature monitoring for enhanced switchboard safety.

Four is the maximum number of items in the comparison tool.

Your search "" did not match any documents or products.

Copied to clipboard

A minimum of two items are required to use the comparison tool.

Sorry, we can't get that information right now.

The wireless and maintenance-free (without battery) sensors use energy-harvesting technology, meaning they can be positioned anywhere in your switchgear assembly without any additional power supply, even in areas that are no longer accessible after completion of the panel system. They provide permanent, 24/7 temperature monitoring of all exposed busbar sections, regardless of the environment, thereby avoiding inaccuracies due to external temperature increases. All data are transferred to the DIAGNOSE controller via an internal protocol based on a frequency of 2.4 GHz. With an accuracy of ± 2 °C, the sensors enable trend analysis and the timely detection of hot spots before an arc flash can occur during normal operation of the switchgear assembly. Thanks to the temperature measurement range from 0 °C to +150 °C, you will always be on the safe side when it comes to monitoring the maximum busbar temperature in low-voltage assemblies.

The system configuration is uploaded and saved to the DIAGNOSE controller, which is the heart of the Eaton DIAGNOSE system. The threshold limits for the different field/section configurations are already pre-configured before delivery. After starting the DIAGNOSE system, all the data/temperatures collected will be saved for one month. After that, the data saved first will be gradually overwritten. Thanks to its large memory capacity, gathering data over the course of several years does not pose any problem for the DIAGNOSE controller. Should a software update become necessary while the internet connection is not active, this can also be implemented in offline mode via the USB drive. The aluminium casing is certified for permanent use in industrial environments with ambient temperatures from -40 °C to +70 °C. Thanks to its robust design, the DIAGNOSE system is fully protected against the shocks and vibrations that may occur in switchgear assemblies during operation.

The visualisation of information takes place via a graphical user interface directly on the panel system (display) or remotely via a laptop or tablet. Thanks to the Modbus TCP connection, Eaton DIAGNOSE can be integrated into any parent BMS/SCADA system. The user interface, which is used for the operation and configuration of the DIAGNOSE system and for displaying the measured values, is an integral part of the controller firmware. No additional software is required, apart from the XML file which can you can download from the xEnergy configurator after finalising your switchgear configuration.