Download document () of 20

Download

You have exceeded the download limit

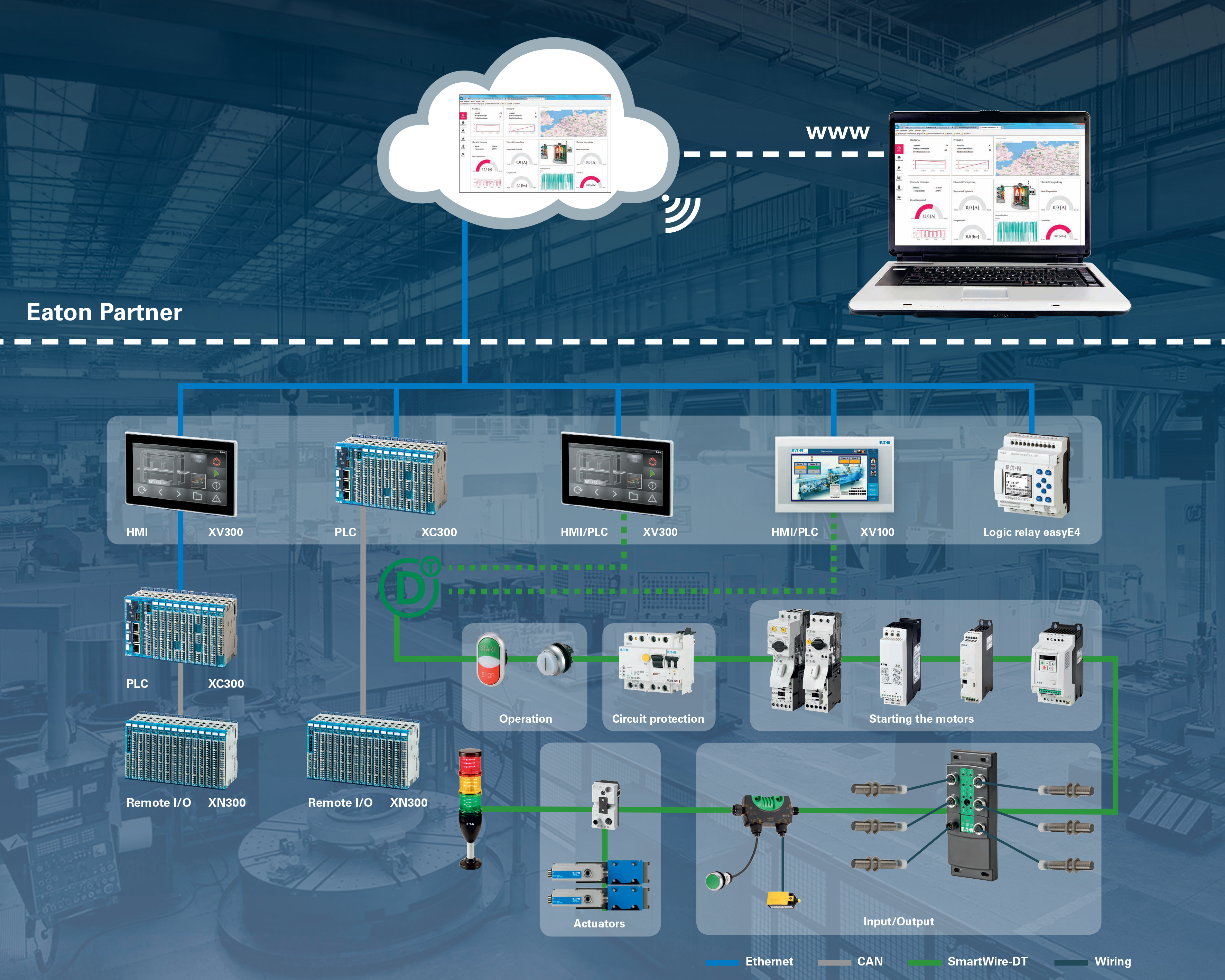

Our goal is the smart factory of the future. We'll drive integrated process optimizations based on the digitized data, so that we can say: 'The production data is available.' Then we can combine data from production and logistics in order to create additional opportunities throughout the value creation process.

Award-winning IoT solutuions

While developing our offer packages for IoT projects, we placed special emphasis on quick and simple implementation, IT security and the use of standard communications protocols. As a result, the predictive maintenance portal has been set up as a centralized cloud service that operates strictly in accordance with German and European data protection guidelines – with maximum security and redundancy.This is only one of the reasons why Eaton’s cloud service offering was one of the winners of the 2017 Industry 4.0 Innovation Awards, which are handed out each year by Germany’s ETZ magazine.

The first step when setting up a digitization project is to understand the challenge. Is is about monitoring machine usage and deployment? Do you want to improve machine performance and availability with predictive maintenance or improvements in the machine design? By today capturing and analysing operational data is easier than ever before and can give you a tremendous insight into the key elements of you machine or system. The data can help you to improve your processes, safe costs and increase output. The tools and infrastructure are all available: new or retrofit machines can become IIoT-ready by adding additional components for sensing and measuring and data can be handled securely via different communication or IT-systems.

Start your digitization project by contacting our Eaton support who will develop the right solution for you based on your requirements. Our brochure gives you a first overview about the available products and capabilities.