문서 다운로드 () / 20

다운로드

다운로드 한도를 초과했습니다.

Virtually all electronic devices from portable electronics and consumer devices, automotive, military and aerospace applications require some degree of protection against overcurrent events. The most economical and common form of overcurrent protection is the fuse. Eaton offers an extensive selection of fuses in a variety of configurations. Selection of the proper fuse for a specific application involves consideration of a staggeringly large number of parameters, fuse technology webpage will review basic fuse operating, application and selection criteria.

Overcurrent fuses serve two main purposes:

An overcurrent event exists when the normal load for a circuit is exceeded. It can either be an overload or short circuit condition. Components and equipment can be damaged by both types of overcurrents.

An overload condition is any current flowing within the circuit path that is higher than the circuit’s normal full-load current. An overload is typically two to five times the magnitude of a circuit’s normal operating current.

A short circuit condition is an overcurrent event that leaves the normal current path, and which greatly exceeds the normal full load current of the circuit by a factor of tens, hundreds or thousands.

During normal load conditions, a fuse must carry the normal operating current of the circuit without experiencing nuisance openings. However, when an overcurrent occurs, the fuse must interrupt the overcurrent and withstand the voltage across the fuse after internal arcing.

To properly select a fuse the following criteria must be considered:

Ambient temperature is the temperature of the air immediately surrounding the fuse and is not necessarily room temperature. All electrical characteristics of a fuse are rated and validated at an ambient temperature of 25 °C. Both higher and lower ambient temperatures will affect a fuse’s opening and current carrying characteristics. This effect is demonstrated in temperature derating curves which are found on the fuse datasheets.

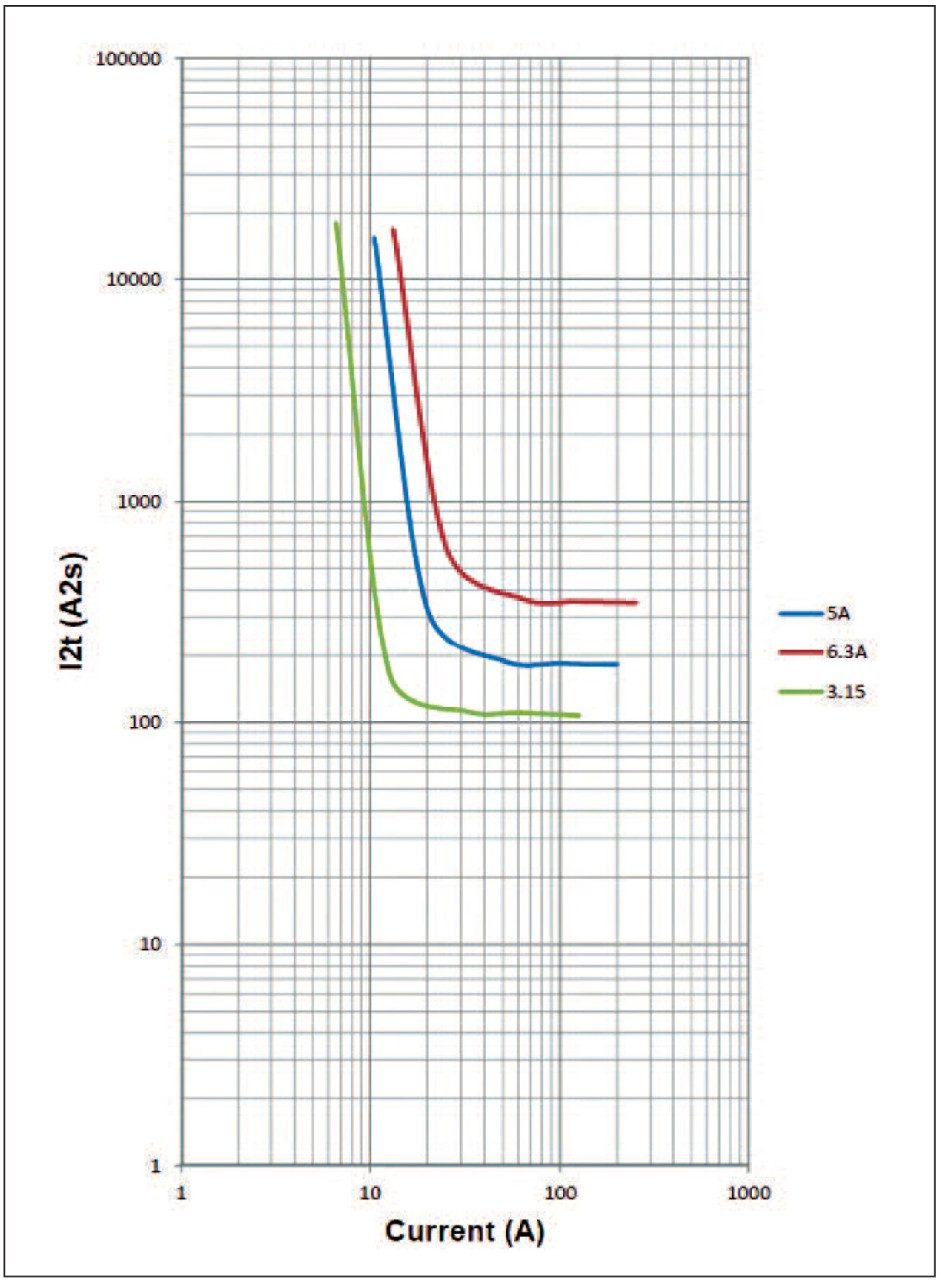

The melting integral of a fuse, commonly referred to as I2t, is the thermal energy required to melt a specific fuse element. The construction, materials and cross sectional area of the fuse element will determine this value. Each fuse series and ampere rating utilize different materials and element configurations; therefore, it is necessary to determine the I2t value for each fuse. Tests to determine the I2t of a fuse are the rated current with a time constant of less than 50 microseconds in a dc test circuit. High-speed oscilloscopes and integral programs are used to measure very accurate I2t values. I2t data is depicted in a time vs. current graph (Figure 1).

The melting I2t of a fuse is one of the values used to assist circuit designers when selecting and properly sizing a fuse in a specific application. It can be compared to the thermal energy created by transient surge currents in a circuit.

A time current curve represents the relationship between a fuse’s melting or clearing time and the magnitude of RMS or DC current. The characteristics represented on most published graphs usually indicate a fuse’s average melting time when subjected to a certain level of current. The curves will typically demonstrate the ability to carry 100% of rated current. They also represent the fuse’s ability to open within the maximum opening time at designated overload points (typically 135% to 300% of the fuse rating).

Time vs. current curves offer a useful design aid for engineers specifying a fuse type or rating for an application. It is, however, recommended that fuse samples be tested in the actual application to verify performance.

Transient surge or pulse currents are used to describe wave shapes that result from any startup, inrush, surge or transient currents in a circuit. The pulse currents are normal for some applications.

It is therefore important to size the fuse properly to allow these pulses to pass without nuisance openings or degradation of the fuse element. The fuse must then open within the limits specified by UL and CSA standards if the overload condition continues. The ability to resist surges is a function of the fuse design and/or classification relative to the surge pulse, duration frequency and so on.

Pulse currents can produce thermal energy that may not belarge enough to open the fuse but could possibly cause element fatigue and decrease the life of the fuse. To properly size a fuse and determine its surge withstand capability, the circuit’s pulse energy should be determined and compared to the time current curve and I2t rating of the fuse. The fuse’s melting I2t value must be greater than or equal to the pulse I2t multiplied by a pulse factor.

The peak current and decay time define the pulse current characteristic or waveform. Pulses can generate different waveform shapes, which determine the formula used to calculate the pulse energy or I2t. Figure 2 shows how to select the appropriate waveform and its corresponding pulse I2t calculation.

A fuse’s capability to withstand a surge pulse without causing thermal stress to the fuse element, which may result in nuisance openings, can be determined once the circuit’s pulse I2t is calculated. A circuit designer needs to properly size the fuse so that the fuse’s melting I2t value is greater than or equal to the pulse I2t multiplied by a pulse factor Fp (I2t fuse ≥ I2t pulse x Fp).

The pulse factor is dependent on the construction of the fuse element. A wire-in-air constructed fuse element (e.g., ferrule fuses, 6125 and 1025 series) will be affected by the number and frequency of surge pulses the fuse is subjected to over the lifetime of the device. This construction design utilizes low-meltingpoint metals plated or deposited on the main element material to cause an “M” effect. If the fuse is sized improperly, low-level pulse currents may cause the low-melting-point metals to alloy to the element without completely opening the element.

A series of pulse currents will eventually create enough heat to shift resistance or even permanently open the fuse. It is important, therefore, to take into account the number of pulse currents to which the fuse will be subjected.

Solid matrix fuses (e.g., 0603FA or 3216FF sized surface mount fuses) do not currently use an “M” effect for the element construction. The element will only then be affected by the thermal energy of each pulse, and it will not normally degrade as a result of the number or frequency of pulses.

Table 1 can be used to determine pulse factor (Fp). For example, a pulse current with an I2t of 0.0823 and a pulse factor, Fp=1.25 would require the selection of a fuse to have a melting I2t greater than or equal to 0.1029.

It is important to note the melting of I2t values of the fuse and pulse current that are compared must be calculated or tested at the same test conditions; most importantly the magnitude of the peak current must be the same. For example, if the pulse’s peak current is 15A, then the fuse’s melting I2t must be calculated at 15A as well to fully understand its electrical characteristics at that magnitude of current.

Table 1.

Pulse Factor, Fp

Table 2.

Physical sizes of traditional ferrule fuses

Chip fuses

The patented Solid Matrix chip fuses provide reliable overcurrent protection to secondary circuits found in mobile phone handsets, battery packs, digital still cameras, portable devices, printers, notebook computers, televisions, automotive instrument panels, battery packs, and more. Its excellent cycling characteristics, small footprint, and SMD package provide the most effective, reliable overcurrent protection solution for today’s - and tomorrow’s - technologies.

Brick fuses

The patented brick fuses provide the excellent inrush withstand capabilities in a space saving SMD package needed in many of today’s more demanding applications such as power supplies, base stations, televisions, computers, white goods, and motor control circuits among others.

Radial leaded fuses

Eaton offers Bussmann series space-saving radial leaded fuses for the global market to provide cost-effective primary circuit protection in space constrained applications such as power adapters, televisions, handheld consumer prodycts, white goods, and more.

IEC & UL Electronic fuses

In addition to SMD and thru-hole device fuses, Eaton offers a offers a full range of Bussmann series traditional electronic fuses designed to IEC standards (5mm product line) and UL standards (1/4” product line). Both product lines offer a cost-efficient overcurrent protection solution for a wide range of applications including power supplies, white goods, motor control equipment, and set-top boxes.

Ampere Squared Seconds I2 The melting, arcing, or clearing integral of a fuse, termed I2t, is the thermal energy required to melt, arc or clear a specific current. It can be expressed as melting I2t, arcing I2t or the sum of them, clearing I2t. |

Overcurrent A condition that exists in an electrical circuit when the normal load current is exceeded. Overcurrent conditions take on two separate characteristics: overloads and short circuits. |

Arcing Time The amount of time from the instant the fuse link has melted until the overcurrent is interrupted, or cleared. |

Overload Can be classified as an overcurrent condition that exceeds the normal full-load current of circuit by two to five times its magnitude and stays within the normal current path. |

Clearing Time The total time between the beginning of the overcurrent and the final opening of the circuit at rated voltage by an overcurrent protection device. Clearing time is the total of the melting time and the arcing time. |

Resistive Load An electrical load that is characterized by not drawing any significant inrush current. When a resistive load is energized, the current rises instantly to its steady-state value, without first rising to a higher value. |

CSA The CSA Group works with businesses, organizations and code authorities testing and certifying products. |

RMS Current The RMS (root mean square) value of any periodic current is equal to the value of the direct current which, flowing through a resistance, produces the same heating effect in the resistance as does the periodic current. |

Fast Acting Fuse A fuse that opens very quickly during overload and short circuit conditions. This type of fuse is not designed to withstand temporary overload currents associated with some electrical loads. UL-listed or recognized fast acting fuses typically open within five seconds, maximum, when subjected to 200% to 250% of its rated current. IEC60127-4 has two categories of fast acting fuses:

|

Short Circuit An overcurrent condition that leaves the normal current path and greatly exceeds the normal full-load current of the circuit by a factor of tens, hundreds, or thousands times. |

Ferrule Fuse A tubular fuse with a glass or ceramic body with metal end caps which serve as termination points to clips used to facilitate insertion and removal. |

Time Delay Fuse A fuse with a built-in time delay that allows temporary and harmless inrush currents to pass without operating; and is designed to open on sustained overloads and short circuits. UL-listed or recognized time delay fuses typically open in two minutes, maximum, when subjected to 200% to 250% of rated current. IEC has two categories of time delay fuses:

|

Fuse An overcurrent protection device with a fusible link that operates and permanently opens the circuit in the event of an overcurrent condition. |

UL UL is a global certification company that sets safety standards for electrical commercial, industrial and consumer products. |

IEC The International Electrotechnical Commission is the world’s leading organization for the preparation and publication of International Standards for all electrical, electronic and related technologies. |

Voltage rating A maximum open circuit voltage at which a fuse can be used while safely interrupting an overcurrent. Exceeding the voltage rating of a fuse impairs its ability to safely clear an overload or short circuit. |

Fill out this form if you would like to be contacted by an Eaton Electronics representative.