Download document () of 20

Download

You have exceeded the download limit

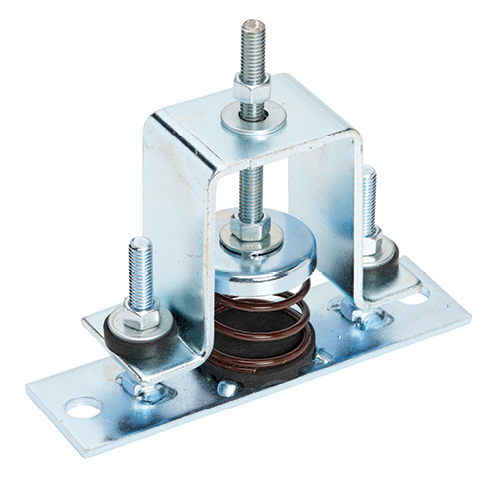

Vibration mounts are used to keep mechanical and electrical equipment from transmitting shock, vibration, and noise to the building. Some examples of the types of machines that use vibration mounts include switchgear, transformers, boilers, cooling towers, and compressors.

Without good vibration control, expensive equipment may fail faster, produce inaccurate results, and even make noise. In addition to vibration caused by motors, fans, and other equipment, some installations may suffer from seismic activity that can create acute and damaging levels of vibration. If frequencies of vibration are allowed to pass into the structure, they may cause significant damage to the building and surrounding systems.

The importance of vibration isolation efficiency

Reduction of vibration does more than just eliminate a nuisance; it can also help prevent a variety of problems, such as:

Vibration isolation mounts are used to help minimize or prevent noise and vibration from transferring between equipment and floor or solid support structure. Typical applications include air handling units, air conditioners, compressors, pumps, machine tools, motors, business machines, transformers, furnaces, etc.

For more information, visit resources to view or download the Seismic Mechanical, Electrical and Plumbing catalog.