Download document () of 20

Download

You have exceeded the download limit

The U.S. electrical grid has been in place for decades, and by and large has been a dependable electricity distribution network. But as a result of decarbonization of production, electrification of transportation, and extreme weather events, centralized production and distribution is no longer as reliable as it once was.

With grid dependability waning, many government institutions, businesses, and communities are turning to microgrids to keep the power on.

Understand the application and assets needed to engineer the right microgrid solution for your project.

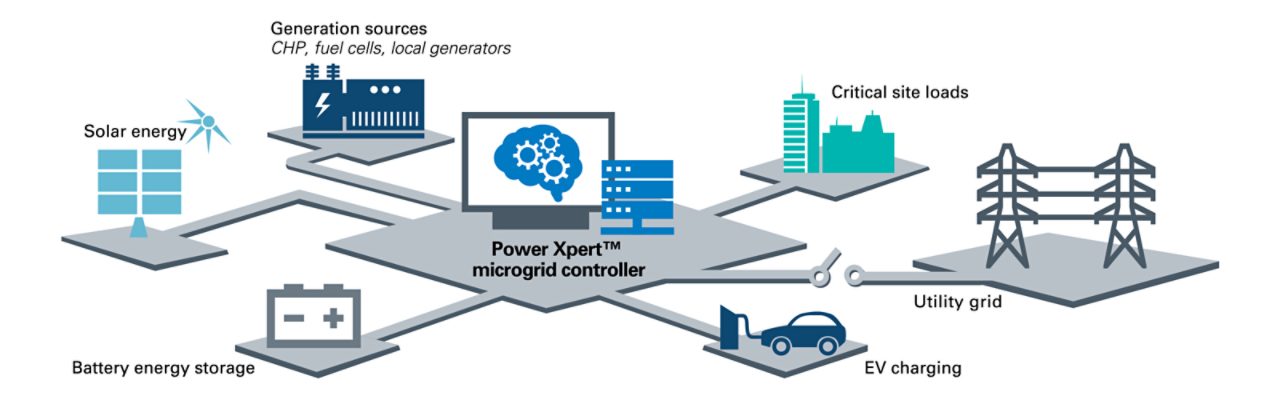

A microgrid is an interconnected electrical system of multiple generation sources and controllable loads that can operate in parallel or independently from the utility grid to keep the power flowing during an outage. It provides a reliable solution for unexpected power loss and energy management by balancing energy demand, optimizing energy usage, and reducing operating costs and carbon emissions. The generation sources are often referred to as distributed energy resources (DERs) that are decentralized assets controlled as an integrated system.

A microgrid coordinates power generation assets that can either work with a utility provider to augment their production or operate autonomously to power critical operations. Often consisting of traditional fossil fuel generators, as well as renewable sources such as wind, solar, and energy storage, microgrids work to generate and optimize energy usage to provide resilient, efficient, and sustainable electricity solutions.

Intelligent microgrid control systems are used to enable the various microgrid components and DER assets to operate in a coordinated way. You can think of the microgrid controller as the conductor of the DER orchestra.

A controller is the brains of a microgrid. An optimized combination of local and system control is used to integrate generating and load management assets, such as distributed energy resources (DERs). The local controller provides semi- autonomous and fast device control, maintains operation within connected equipment limits, provides local sequencing and alarm management and includes an integrated sequence of events recorder.

A system controller interfaces with upstream SCADA and optimizes the operation of power system assets (sources and loads) through the downstream local controllers. The system controller can support various system-wide applications such as optimal source dispatching, demand control, renewable firming and more.

A microgrid is as unique as the business, community, or government institution that deploys it. The solution is never "one-size-fits-all"; by understanding an organization's needs and wants, microgrid developers can identify the applications and assets needed to custom engineer an appropriate solution.

Organizations typically fall within the spectrum of prioritizing three goals: resilience, efficiency, and sustainability. Of course, every customer would like to build a microgrid that "does it all." However, while benefits certainly overlap, building a solution that entirely satisfies all three objectives can be cost-prohibitive.

The need for consistent, always-on power is a huge concern for many companies and residential communities. Cybersecurity threats and extreme climate-related weather emergencies like wildfires, hurricanes, and winter storms are impacting access to reliable power. Many states have awarded grants and passed disaster-response legislation to invest in microgrids and similar technologies to help reduce or eliminate power loss. More than ever, our global energy and infrastructure must be able to withstand extreme conditions. Our lives, communities, and businesses depend on it.

Additionally, remote communities and developing nations are exploring microgrids for resilient energy as well as to lessen their dependence on fossil fuels, especially oil and diesel. Resilience is about bolstering critical operations and the ability to recover quickly from a crisis. Microgrids can play a key role in providing a more resilient energy infrastructure and are an investment in business continuity.

Many governments, corporations, and institutions look to microgrids for financial benefits. These benefits are achieved by two primary methods: cost avoidance and external monetization. Cost avoidance can take many forms, such as maximizing freely produced energy from renewable sources like solar and wind. When energy storage is added to renewable sources, it enables the freely produced power to be a dispatchable resource. That free power can then be leveraged during times of high utility grid energy costs to reduce peak demand charges, providing utility bill savings. External monetization occurs by participating in demand response programs or by selling energy and frequency regulation services to a third party such as independent system operator (ISO) or virtual power plant (VPP).

Organizations around the world have established environmental, social, and governance (ESG) goals. These goals very often contain milestones or pledges to reaching a carbon neutral operations footprint by a given date. Microgrids can be a significant tool in reaching decarbonization goals while providing stakeholder value through energy cost savings and operational resiliency. A common challenge in powering business operations from renewable sources such as solar or wind is their intermittent nature. The sun isn’t always shinning or the wind blowing. The rise of affordable battery energy storage systems (BESS) has made popular a control technique known as renewable firming. Microgrids leveraging a combination of renewable sources and BESS store excess energy during times of peak generation and discharge it when renewable sources are not producing or producing less than required to support the load.

As the energy transition advances, we're helping companies and communities around the world simplify their energy systems and safely transition to the low-carbon future.